History

Cotel Telecom was established to provide Radio Communications systems and services to the North Sea Oil and Gas Exploration industry. The business rapidly expanded, to provide Microwave and VHF communications within the Oil and Gas Exploration sector of the Southern Omani Desert for Shell and P.D.O. Other opportunities arose, providing consultation and planning advice to Pakistan Railways in order to facilitate their migration from a traditional copper cable, Morse Code based communications system to an integrated Microwave Voice and Signalling solution.

In conjunction with the above, Cotel was also developing a customer base within the UK. A wide range of Radio Communications systems and services are provided to a wide range of customers, and each requirement is different and unique. Customers include the NHS, Argos Distribution Centres, Mines and Quarries, Food Production Organisations, Farming and Agriculture and the Tourist industries.

The wide range of customers dictate a wide range of solutions, as each customer is unique in their demands and requirements. Quality and reliability are an essential requirement of everything Cotel would undertake, in terms of quality of staff and the quality of the products and services supplied by ourselves.

North Sea gas pumping stations control the flow of gas from the main exploration rig to shore. Telemetry links are used extensively to monitor and control gas flow, also turning the pumping stations ON and OFF as required by either demand or maintenance, from either the main supply rig or onshore control. Maintenance teams visit the gas pumping stations either by helicopter or Supply Maintenance Vessel, depending on weather conditions and the level of maintenance/repair required.

Burning off excessive gas from a new North Sea well prior to commencing the process of pumping the Crude Oil ashore. The heat generated even at that distance is intense.

Oil and Gas platforms are unique working structures and a unique range of Wireless Technology systems are provided to keep the platform working. Satellite communications between the platform and their global operational HQ in the US and UK, Microwave links to control remote pumping platforms, ship to ship and ship to shore communications, Aviation communications linked with helicopter support flights, distress communications and on-platform Atex-approved communications for operational staff working on the production process.

In addition, staff welfare communications are provided, including Satellite broadband, Satellite T.V and Satellite phone facilities for that very important call home.

All the above services need to operate 24/7/365 in order to ensure the safety of all the staff and the cost effective and operational efficiency of the production platform.

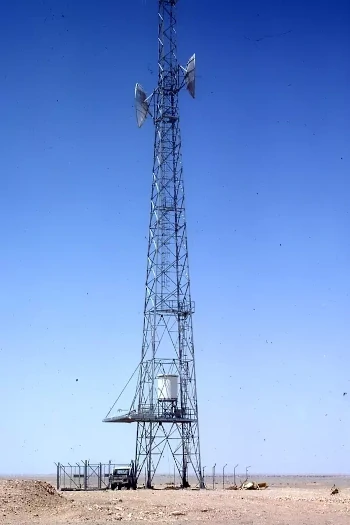

One of 25 microwave towers providing the communications link between Muscat and Marmul, located within the Southern Oman Desert. As well as voice and data, each tower provides a vital communications link between production and exploration teams working within the southern part of Oman.

Marmul Terminal located close to the main accommodation area. Initially powered by a diesel generator, charging the standby battery facility. Note the Diversity Aerial scheme. Microwave Terminal equipment and VHF communications equipment, installed in the environmental shelter at the tower base, enable contact with the production and exploration teams operating within the area.

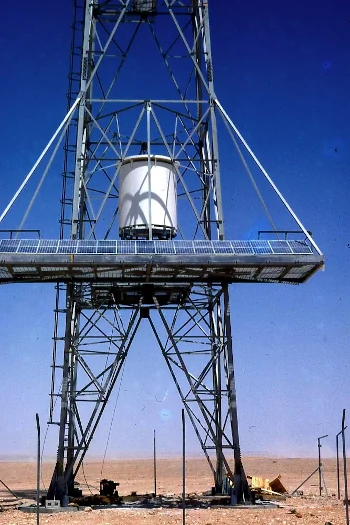

Visual showing a local area tower site/link, under construction, with environmental shelter housing the microwave and VHF communications equipment. Note the solar panels; behind these are rechargeable batteries ensuring 24/7/365 operation.

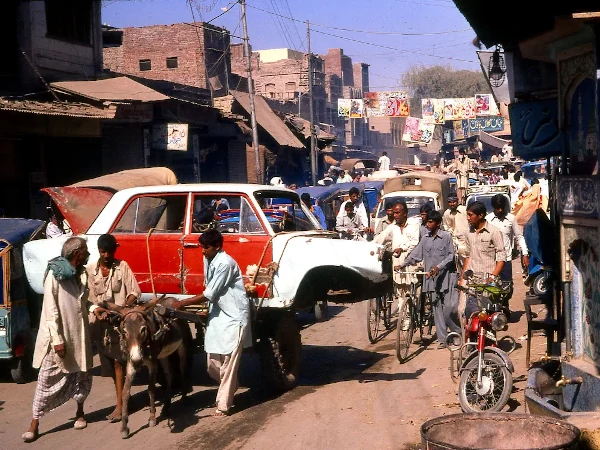

Pakistan, a remarkable country of extremes and varying contrasts, with the additional problems of refugees from the conflict in Afghanistan, economic and political turmoil.

Contrast the stunning architectural history and wealth compared with wide spread poverty for majority of the population. Whichever facet of life you look at, the contrasts are always poles apart.

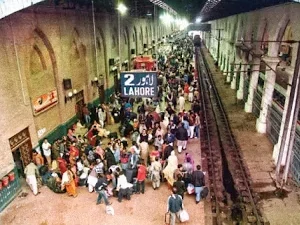

The degree of poverty has contributed towards the extensive use of the railway network within Pakistan. Private car ownership per head of population is extremely low, and the interconnecting road network between towns and cities is of a very poor quality. This results in the extensive use of the railway network within Pakistan as the only cost-effective method of mass transport available to the population, and for the distribution of freight and raw materials throughout the country.

During British rule, the Indian Empire saw the foundation and rapid development of the railway network throughout the India subcontinent. The majority of the infrastructure, associated signalling and communications system had been established during this period up to the late 1930s, with very little change since.

After partition in 1947 and the formation of Pakistan, the railway network continued to grow in order to cater for the increasing demand of the growing Muslim population. The use of established pre-partition railway technology had been used during this period of expansion, especially with the signalling and communication systems not being upgraded to meet demand.

The process of expansion of the track network, passenger numbers and outdated infrastructure, led to an inability of the already outdated telegraphic communications systems (using morse code to communicate between signal boxes/adjacent stations) to keep ahead of the volume of train movements and an inability for equipment defects, delays and timetable alterations, to the adequately and efficiently communicated between train controlling zones and local signalling boxes.

These shortcomings had in-turn contributed to a large number of tragic train accidents, where hundreds of people had lost their lives and essential infrastructure had been destroyed. Other contributing factors to the increasing tolls of accidents on Pakistan's railways had been local farmers in rural areas cutting down the overhead trackside telegraph wire to fence in their herds of goats and sheep.

Due to the volume of passenger numbers on each train, the numbers of dead and injured would always be very high.

Located in the backstreets of Karachi. Visual showing the world's most environmentally friendly car transport.

During the preliminary planning stages for the Microwave Communication Development, the only maps available at the time from the Pakistan Government had been produced by the British Army during the early 1930's. These had not been adequate for the purposes of developing a Microwave Communications strategy for the Railway Network.

In response to this, groups of survey teams were established covering the whole Railway Network. Using the Magnavox MX1502 Satellite Surveyor, the purpose was to determine the exact location of each station, control hub and the height above sea level. Such data was used to determine the terrain along each pathway and any possible obstructions. In addition, the existence of parallel or intersecting frequency systems and interference possibilities had been investigated.

At the time, the latest Satellite Surveyor was the Magnavox MX1502 - these had been extensively used during the Field Survey process of the Pakistan Railway network, along with Anritsu Spectrum Analysers. Each team consisted of a Cotel Staff Team Leader and locally recruited Field Service Vehicle Driver, a Surveyor (for local area profiles), Foreman and four Labourers to carry the Magnavox, Anritsu Spectrum Analyser, associated batteries and aerial system from the vehicle to the site monitoring point.

On completion of the Field Survey and the design phase of the Microwave system completed, the full report, analysis data and recommendations had been passed onto the Railway Minister for the tendering process to start. The contract was eventually awarded to Kentron International, an American company based in Dallas, Texas.